I see many people struggle to stand out in the footwear business. They feel stuck. I offer a simple way to create unique EVA molds.

I make customized EVA shoe molds by choosing the right materials, forming precise designs, and making by the best equipment, like CNC machines. Then I test for durability. This process is straightforward, but it requires patience and the right equipment.

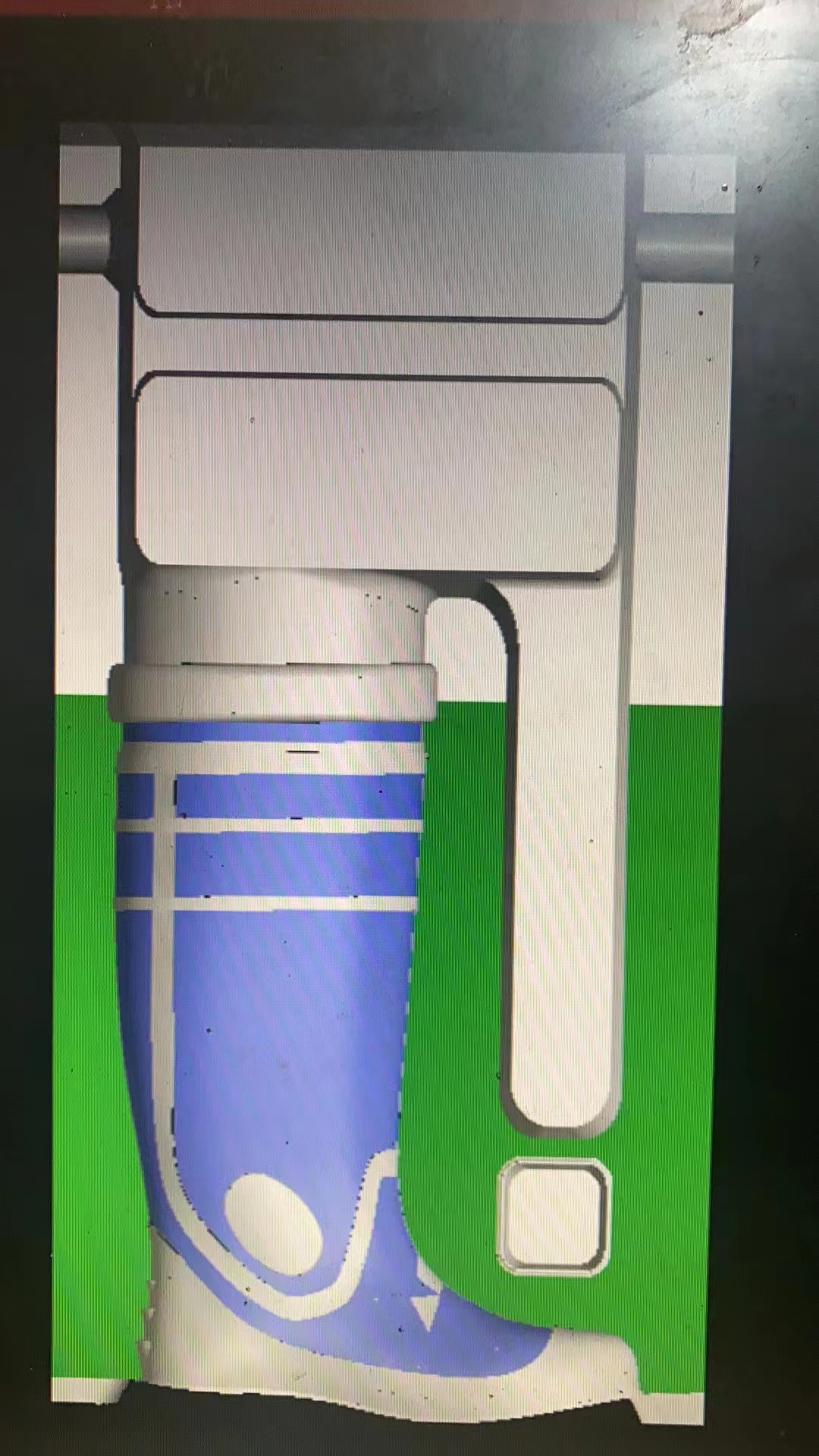

Customized EVA boot Mould

I want to share more details. I will explain my approach and help you understand why customized EVA shoe molds can make your products more competitive. Keep reading to learn the full process.

Why do I need customized EVA shoe moulds?

I see many shoe manufacturers trying to follow generic templates. They hope for sales to improve. I believe a custom mold creates a unique style and brand identity.

You need customized EVA shoe molds because they offer distinct shapes, better comfort, and brand recognition. You also get greater control over color schemes, sizes, and design details. This helps you stand out in a competitive market.

Customized EVA Shoe

Dive deeper: Benefits, brand identity, and cost considerations

I discovered the advantages of custom EVA shoe molds when I worked with small factories. They struggled to differentiate their products from big brands. Their shoes looked similar to everything else on the market. So I advised them to shift to custom solutions. Below is how I break down the topic:

1. Brand Identity

Many shoe businesses need a strong brand to gain loyal customers. I learned that a new shoe design can catch people’s attention quickly. If the mold has a special pattern or shape, customers remember it. They share their experience. This leads to positive word-of-mouth, which boosts long-term growth.

2. Fit and Comfort

I think it is essential to fit different foot shapes. When I offer a custom mold, I can adjust the shoe structure to match specific customer demands. EVA foam is lightweight, flexible, and absorbs shock. These properties help people feel comfortable while walking or running. With a custom mold, I can fine-tune thickness, arch support, or toe shape.

3. Cost and Production Scale

I know cost is a concern. At first, custom molds may seem expensive. However, I have seen that the extra expense can pay off in market differentiation. I also found that once you have the right mold, you can produce the same style in mass quantities. This balances the initial investment.

Below is a brief overview of considerations:

| Factor | Description | Impact on Business |

|---|---|---|

| Brand Identity | Unique patterns and shapes | Builds recognition, stands out in the market |

| Comfort | Adjust thickness and shape for foot support | Improves customer satisfaction |

| Cost | Higher initial investment | Can return profit through uniqueness |

| Style Options | Wide color and design possibilities | Expands target market reach |

I have seen these factors come together to help a factory produce shoes that feel unique. Customers notice differences in shape, comfort, and design. In the long run, custom molds help businesses grow.

How do I design the perfect EVA shoe mold?

I notice many designers face confusion when creating molds. They are unsure about the technical steps. They worry about fit, durability, and consistent production.

I design the perfect EVA shoe mold by focusing on accurate measurements and shape. Then I use a modeling approach that accounts for thickness and foot arch. Lastly, I test prototypes for comfort and function.

Designing EVA Shoe Moulds

I remember when I first experimented with mold design. I used to rely on rough sketches and guesswork. That led to errors. Over time, I learned a more detailed approach. I will share it in steps below:

Here is a step-by-step process for making EVA shoe molds:

1.Design the Blueprint – We start by creating a 2D design drawing, including all necessary details such as dimensions, structure, and branding elements like the customer’s logo.

2.Create a 3D Model – Based on the 2D blueprint, we develop a 3D design to visualize the final mold structure more accurately.

3.Build a Wooden Model – A wooden prototype of the mold is crafted to ensure all dimensions and design aspects are correct before full-scale production.

Wooden model

4.Confirm the Wooden Model – The wooden model is reviewed and approved by the client to ensure it meets their expectations.

5.Mold Production – Once the wooden model is confirmed, we proceed with the mold manufacturing process, using high-quality materials and precision engineering.

6.Testing and Sample Production – After the mold is completed, we test it by producing sample EVA shoes to ensure the quality, fit, and performance.

7.Customer Confirmation – Finally, we send the samples to the customer for final approval before mass production.

I enjoy seeing a finished EVA shoe come out of the mold. It feels rewarding because I know each detail was planned. I remember visiting a small factory in Brazil. Their EVA shoes are unique and popular in the local market,the most important thing is sold very well.And when our customer told us they will buy more EVA shoe molds from us, I am so excited and happy.

Conclusion

Customized EVA shoe molds offer a better fit, unique style, and brand recognition. I believe this approach transforms ordinary footwear into memorable products.