Struggling to maintain high-quality EVA products consistently?

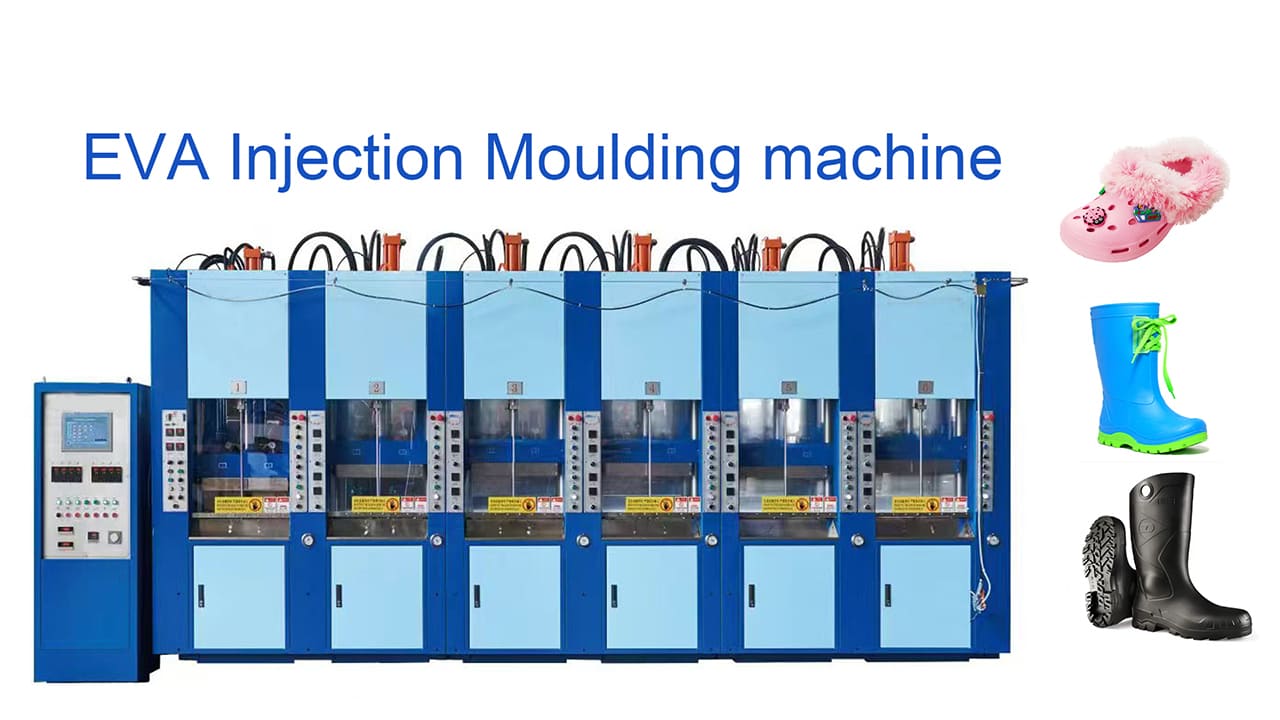

A fully automatic EVA injection moulding machine is an advanced, fully hydraulic,automatic system designed for efficient production of footwear and various other EVA products. It features PLC control and a user-friendly computer interface, ensuring precise and rapid production parameters.

Automatic EVA Injection Moulding Machine

Are you ready to elevate your EVA product manufacturing? Let’s dive into how a fully automatic EVA injection moulding machine can revolutionize your production process.And I believe use full automatic EVA Injection Moulding Machine will dramatically increase your productivity.

What products can be made using an EVA injection moulding machine?

Looking to expand your EVA product line?

An EVA injection moulding machine can produce a wide range of products, from footwear to automotive parts, sports and fitness products,offering versatility in manufacturing.

Diverse Applications of EVA Injection Moulding

The versatility of EVA injection moulding machines allows manufacturers to create various products tailored to different industries. Here’s a closer look:

Footwear

EVA is widely used in the footwear industry due to its lightweight and cushioning properties. With an EVA injection moulding machine, you can produce:

- EVA Slippers: Comfortable and lightweight, perfect for casual wear.

- EVA Rain Boots: Durable and water-resistant, ideal for wet conditions.

- EVA Sandals: Flexible and comfortable, suitable for everyday use.

- EVA Flip-Flops: Popular for beachwear and casual settings.

- EVA Shoes for Children: Soft and safe, designed specifically for young feet.

- EVA Insoles: Provide extra cushioning and support for various types of footwear.

Sports and Fitness Equipment

EVA is also used in the production of various sports and fitness products:

- Exercise Mats: Provide cushioning and support during workouts.

- Yoga Blocks: Lightweight and easy to handle for yoga practitioners.

- Sports Equipment: Durable and flexible components for different sports gear.

Consumer Goods

The flexibility of EVA allows for the creation of a variety of consumer products:

- EVA Bags: Durable and lightweight, suitable for everyday use.

- EVA Toys: Safe and flexible toys for children.

- EVA Protective Gear: Provides comfort and protection in various applications.

| Category | Products |

|---|---|

| Footwear | Slippers, Rain Boots, Sandals, Flip-Flops, Children's Shoes, Insoles |

| Automotive Parts | Floor Mats, Cushioning Elements, Protective Covers |

| Sports & Fitness | Exercise Mats, Yoga Blocks, Sports Equipment |

| Consumer Goods | EVA Bags, Toys, Protective Gear |

By utilizing an EVA injection moulding machine, manufacturers can efficiently produce a diverse range of products, catering to different market needs and expanding their business opportunities.

How do I choose an injection molding machine?

Unsure about selecting the right injection molding machine?

Choosing the appropriate injection molding machine involves evaluating your production needs, machine capabilities, and ensuring compatibility with your products.

Factors to Consider When Selecting an Injection Molding Machine

Selecting the right injection molding machine is crucial for optimizing your manufacturing process. Here are the key factors to consider:

Production Volume

Assess your production requirements to determine the machine’s capacity. High-volume production may require a machine with a higher clamping force and faster cycle times, while low-volume production might benefit from a more flexible, smaller machine.The popular machines on the market now include 6-stations and 8-stations machines, but some manufacturers will also customize 2-stations and 4-stations machines according to customer needs.

Automatic EVA Injection Moulding Machine 2 stations

Machine Specifications

Consider the machine’s specifications such as mold-holder station, clamping force, mold opening stroke,injection speed, and the size of mold holder. These should align with the size and complexity of your products to ensure efficient and accurate molding.

Compatibility with Molds

Ensure that the machine is compatible with your existing molds or the molds you plan to use. Compatibility affects the ease of setup and the overall efficiency of the production process.

Energy Efficiency

Energy-efficient machines can reduce operational costs and are better for the environment. Look for machines with energy-saving features to enhance sustainability and reduce long-term expenses.We suggest to use servo motor (the brand like HYSIS or INOVANCE)

Maintenance and Support

Consider the ease of maintenance and the availability of technical support. A machine that is easy to maintain will minimize downtime and ensure continuous production.

Budget

Evaluate your budget constraints and consider the total cost of ownership, including initial investment, maintenance, and operational costs. Ensure that the machine provides good value for your investment.

| Factor | Considerations |

|---|---|

| Production Volume | Capacity should match your production needs. |

| Machine Specifications | Clamping force, injection speed, shot size. |

| Compatibility with Molds | Ensure ease of setup and efficiency. |

| Energy Efficiency | Look for energy-saving features to reduce costs. |

| Maintenance and Support | Ease of maintenance and availability of technical support. |

| Budget | Total cost of ownership, including initial and operational costs. |

By carefully evaluating these factors, you can choose an injection molding machine that not only meets your current production demands but also supports your future growth and business objectives.

Conclusion

Fully automatic EVA injection moulding machines enhance efficiency and quality in EVA product manufacturing.It has a wide application in EVA products and with automatic EVA injection moulding machine.